Fitting of PCBs and soldering

Our radars are fully digital. Therefore, one link of our production chain consists of fitting and soldering of printed circuit boards which are used to assemble radar hardware. Fitting operations are completed during an automated process using a fitting line, solder paste printer pasty, soldering furnace and a laboratory where manual soldering and fitting of components take place. The true upside of the fitting line is the high degree of automation which facilitates reduction of working time, miniaturization, repeatability of production and, above all, minimization of fitting mistakes. Furthermore, the PCB center workplace uses its own automated optical inspection (AOI) to perform quality assurance and to ensure high quality standards.

The PCB center secures the manual soldering of printed circuit boards, fitting of these boards with power components for soldering in of SMD components on the SMT line, mechanical assembly of boards according to specific configurations and electrical connections and wiring.

Microwave department

The Microwave Department designs and checks the properties of power amplifiers and modules, active and passive components, such as receivers, oscillators, mixers and other support chips. It also develops complex structures exploiting coaxial or wave guide equipment, such as rotary clutches, circulators, various dividers, couplers, antennas, etc. Measurements of passive and active L-S and X-band antennas in a remote zone are in our own testing polygon.

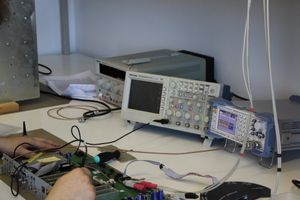

Hardware Department

The goal of the Hardware Department is to activate and validate prototypes of radar blocks, to prepare boundary-scan tests for printed circuits boards and simulation of the signal processing of radar data.